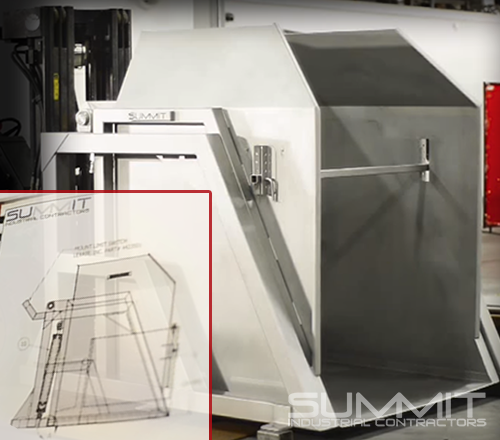

Fabrication Process

After designs are approved, your project moves to our production floor where our team of highly skilled workers and top-of-the-line equipment work in tandem with our engineering team to create your custom system from scratch. Our 90,000 square foot complex allows ample room for us to fabricate, assemble, test, and refine your equipment before it is installed on your main floor, all while maintaining a superior level of quality and craftsmanship.

We continually maintain and upgrade our technology and fabricating equipment, as well as train our team to stay abreast of the latest technology and ensure that we are offering the most efficient techniques to our clients. We also research all components for the highest quality and durability, while also keeping cost in mind.

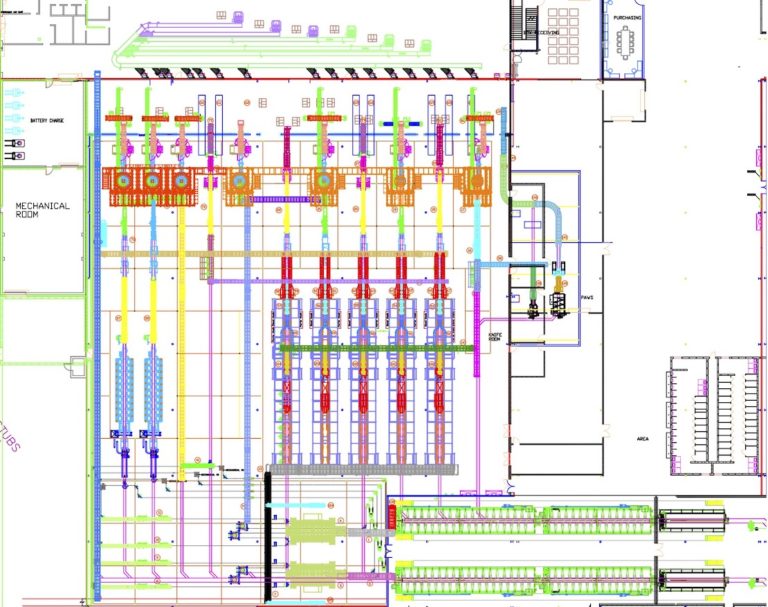

Integration

Once your equipment is ready, our project managers work with you to schedule installation on a timeline that best suits your schedule. On-site installations typically occur on weekends, reducing your downtime and increasing your bottom line during the transition. Our project managers, with a combined 50 years of experience in the field, have the ability to change direction mid-project if necessary, allowing customers the flexibility needed when finalizing an installation.

Our Team

Our elite, professional team dedicates itself to completing jobs on time and on budget. We know that our name is only as good as what we deliver, so we always strive to deliver world-class products with superior customer service. Our grit, determination, and heart shine as we deliver products to both new and returning customers, time and time again.